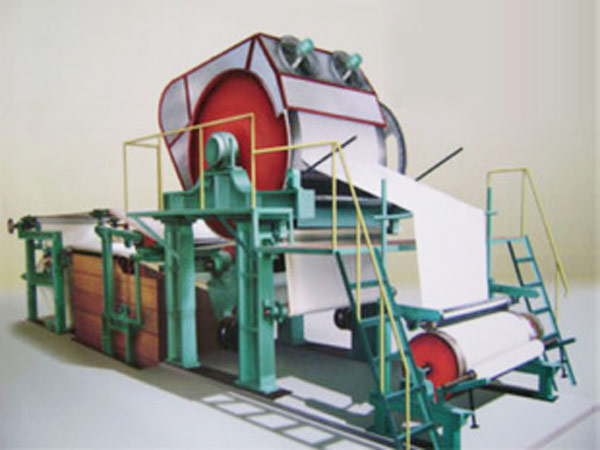

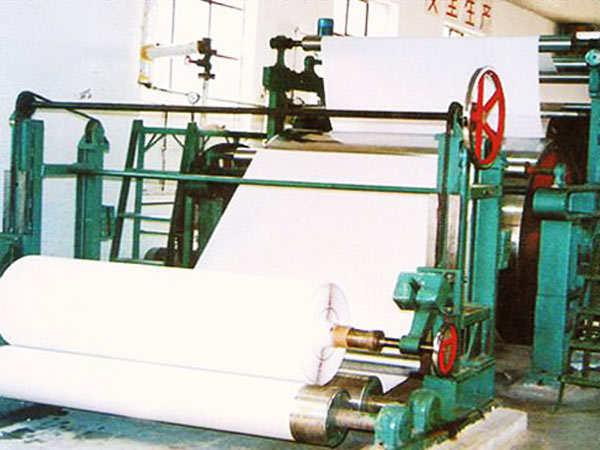

Tissue paper making machine is a set of machinery which is fit for making tissue paper. When we say tissue paper, it refers to all kinds of tissue paper, such as hygienic tissue paper, facial tissues, paper towels, wrapping tissue, toilet tissue, table napkins. The raw material of making these paper can be pulp wood, waste carton, waste newspaper.

With 15+ manufacturing experience, we Beston Machinery has advanced technology, excellent production technology, strong production capacity and excellent product quality. We can assure you short delivery time, first-class product, competitive price and perfect after-sales service. We have exported our tissue paper manufacturing machine to 50+ countries. All of our customers speak highly of we Beston Machinery. Our tissue paper machine has various types of BT-787, BT-1200, BT-1092, BT-1575, BT-1880, BT-2640. If you need to buy the machine, ask the reasonable price now!

Output/day:0.8-0.9T

Weight:20-30g/m2

Net Paper Width:787-900mm

Working Speed:20-80m/min

End paper Dryness:90%-93%

Max. working hours/day:24

Output/day:1-1.2T

Weight:20-30g/m2

Net Paper Width:1200mm

Working Speed:40-50m/min

End paper Dryness:90%-93%

Max. working hours/day:23.5

Excellent Spare Parts of Tissue Paper Making Machine You Can Buy From We Beston Machinery

D type Hrdrapulper

On the basis of traditional machine, the D type hrdrapulper is designed by bringing foreign advanced technology. Its main features are: vookers rotor is off center position which makes the cotact between paper material and rotor more quicker and more frequent. D type hydrapulper can reduce the time of paper handling. And, it can increase the 30% defibering ability without promoting the power and volume. This equipment is the ideal machine for paper making industry used in intermittent and continous breaking virgin pulp board.

Rotary drum type hydrapulper

1. It can finish the fibre pulping and coarse screening with single crash.

2. The pulping density can reach 14%-18%.

3. It has no damage to fiber. Also, it can complete remove plastic, fabric, wet strength, the function of the adhensive tape and other impurities.

4. low power consumption.

The Double-disc Pulp Refiner

The double-disc pulp refiner is an equipment that is used for coarse, refined grinding and continous pulp breaking. It is suitable for grinding straw pulp, virgin wood pulp and waste paper pulp. The advantages of the machine are: high efficiency, lower power consumption and so on.

Vibrating Screen

The vibrating screen is used to screen and remove various impurities in pulp suspension. When it is used for removing section, it can be installed after pulp washing process. When it is used for roughing , it can be installed before pulp washing process. The screen has large vibration amplitude, screening ability, high efficiency, low noise easy maintenance, low energy consumption. Meanwhile, it adopts complete sealed that has less cover area.

Centrifugal Screen

The centrifugal screen is a kind of common screening equipment in pulp and paper making industry. It is mainly used for coarsing and refined grinding after washing. It can remove the other impurities in pulp material, such as chemicial pulp, mechnical pulp and so on. It contains shell, frame, sieve drum, rotor and motor parts.

Horizontal mixer

Horizontal mixer is an mixing equipment that is used in slurry tank underground. It can make the water and pulp mixture have evenness mixing degree. Therefore, it is good for producing the same thickness paper.

Vacuum Pump

Roots vacuum pump is vacuum equipment that is widely used in paper making industry, chemical industry, etc. In paper industry, it is used for vacuum dewatering in fourdrinier and cylinder net part. It can suck dry and wet air and water mixture. But it can not suck granular material, high dust gas or corrosive material.

The High Medium and Low Concentration Desander

Sand remover is mainly used for pulp cleaning and removing impurities. It use the centrifugal theory to remove large adhensive mixture, sand, stone, paraffin, hot melt glue, plastic piece, dust, foam, air, iron dust, oil, ink ion , light impurities. Aomong them, the double cone high efficient desander has the advantages of less cover area, high production capacity, easy operation, high cleaning efficiency, long service life time and so on.

Output/day:2T

Weight:20-40g/m2

Net Paper Width:1200mm

Working Speed:70-100m/min

End paper Dryness:90%-93%

Max. working hours/day:22.5

Output/day:3-4T

Weight:15-30g/m2

Net Paper Width:1700mm

Working Speed:110-120m/min

End paper Dryness:90%-93%

Max. working hours/day:23.5

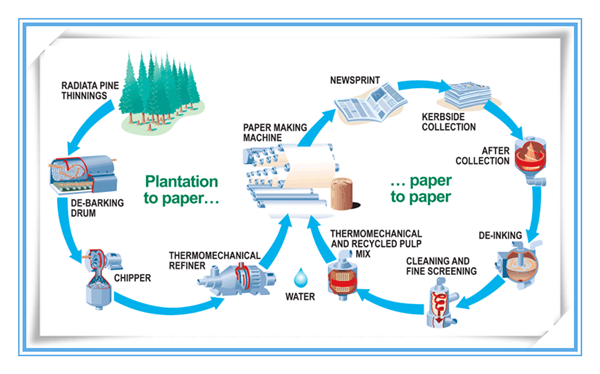

The Tissue Paper Making Process:

1. Putting the raw material material into pool is the first process of making tissue paper(a. waste paper: waste printing paper, newspaper, notebook… b. Wood pulp, cotton pulp, virgin pulp…)

2. The second manufacturing process of tissue paper: beating down the fibre into pulp through hydrapulper. Accorfing to function and shape, the hydrapulper can be divided into two types: D type Hrdrapulper and Rotary drum type hydrapulper. You can choose it on the basis of your requirements.

3. Screening of coarse impurities with shaker to make sure the high quality of paper.

4. Adding medicament and chemical to batching box.

5. Then you can get wet paper product with tissue manufacturing machine.

6. The end tissue making process: pressing and drying to get the actual paper through toilet roll machine, tissue paper cutting machine, tissue paper packing machine.

Output/day:5-6T

Weight:15-30g/m2

Net Paper Width:1950mm

Working Speed:130-160m/min

End paper Dryness:90%-93%

Max. working hours/day:24

Output/day:14-15T

Weight:15-30g/m2

Net Paper Width:2640mm

Working Speed:160-180m/min

End paper Dryness:90%-93%

Max. working hours/day:22.5

As one of the best tissue paper making machine suppliers, we know clearly know about every details of how to produce tissue paper. If you choose to buy our tissue paper manufacturing plant, we will provide you professional installing and worker training guidance. If your workers have a comprehensive understanding of tissue paper manufacturing process, I’m sure they will make high quality tissue paper successfully in a short time. It is one part of our after-sales service. We also will arrange after-sales service staff to help you deal with any difficulties as soon as possible after purchasing our machine.

Why Tissue Paper Manufacturing Industry Develops Fast?

First, the paper industry is a kind of pillar industries. In our life, we can not live without paper. The tissue paper has a close connection to personal health care. If you get into the habit of using tissue paper, you will not stop buying tissue paper in daily life even though the sagging economy.

Meanwhile, tissue paper belongs to fast-moving consumer goods. You use it for one time. Due to high replacing frequency, a certain periodicity, people will have continuous new demand.

Third, according to a recent tissue paper manufacturing project report, tissue paper industry has a rapid growth along with economic development, population growth and the improvement of people’s life quality.

Therefore, tissue paper manufacturing industry has a enormous market. If you have a tissue paper manufacturing business plan, don’t hesitant to invest.

Introduction Of We Beston Machinery:

Scientific and technological innovation:

The high quality demand of people is a magnet to attract tissue paper machine manufacturers’ attention in innovation and reforming new generation of tissue making machine. And also, it is an engine to drive paper making industry. In order to catch up the developing trend of the machine, our factory has put elite research and development team, adequate money into simplifying tissue paper production process, increasing productivity of tissue machine. So, our tissue paper production machine has advanced technology, first-class quality, high productivity, easy operation, long service life time.

Countries we exported:

Our machines have already been exported to over 50 countries, such as Algeria, Egypt, Russia, Ukraine, Australia, Argentina, Brazil, Saudi Arabia, Libya, Syria etc. They all speak highly of the quality our machine and our perfect after-sales service. Our aim is to sell our machines worldwide. We have the strength to fulfill it.

The Commitment To Our Customers:

1. Tissue paper plant with completely designed, technologically advanced

2. Convenient and smooth operation, high operation efficiency

3. Various output capacity and configuration of tissue paper production line can be customized based on different needs of customers.

Because of large demand for tissue paper machinery, there are a number of tissue paper machine suppliers on the market. When you buy machine for manufacturing tissue paper, you should choose one reliable partner from these tissue machine manufacturers. So, if you are interested in our machine, please feel free to contact us to get tissue paper making machine price! We hope to establish long term cooperation with you!